Advantages and Disadvantages of PET Printing Technology in the Textile Industry

Printing technology is an important part of the uniform manufacturing industry, especially when it comes to printing logos on uniforms and T-shirts. Among the existing printing techniques, PET printing has emerged as an optimal solution with many outstanding advantages. However, it is not without its disadvantages. This article will provide a detailed look at the pros and cons of PET printing on uniforms, helping you gain a more comprehensive understanding of this technology.

What is PET printing technology?

In PET is a printing method that uses PET film (Polyethylene Terephthalate) as a base for printing images and designs on textile products. Thanks to its high strength and quick production time, PET has become the ideal choice for producing uniforms, including t-shirts and other clothing products.

The operating mechanism of PET printing technology

When applying PET printing technology, a layer of PET film is printed with images and logos according to the desired design. Afterwards, this film layer is coated with a layer of adhesive, dried, and pressed onto the fabric surface using heat and pressure from a press machine, creating a strong bond between the ink and the fabric. This process not only creates sharp images but also determines the durability of the product.

Practical applications of PET printing

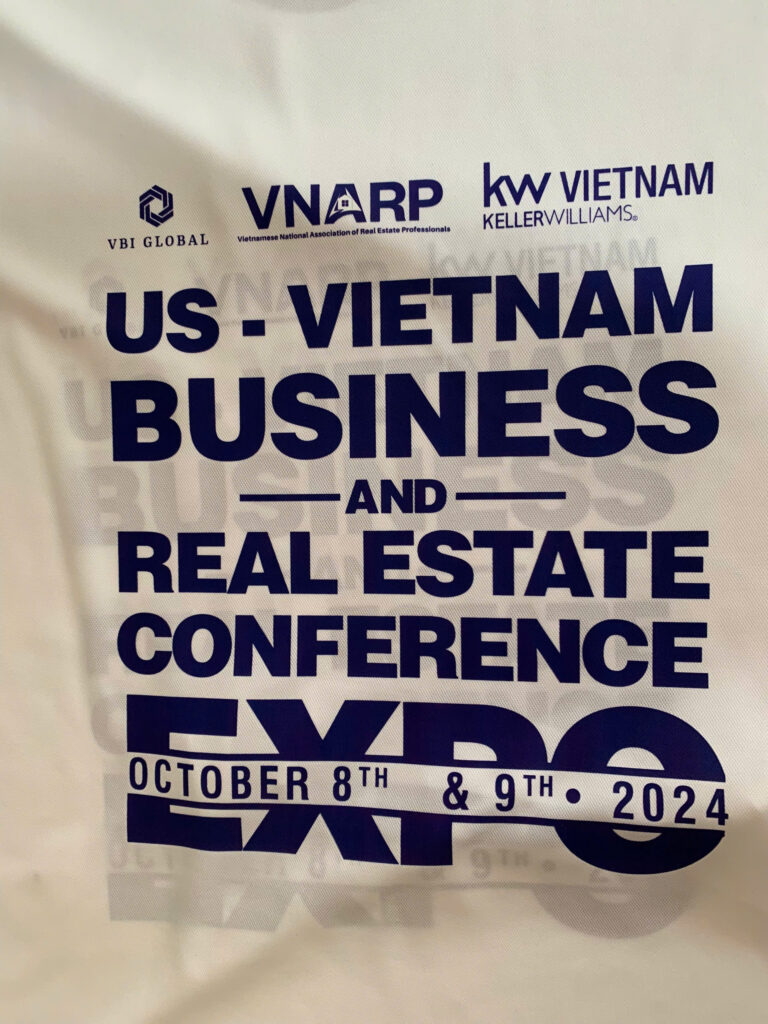

PET printing technology is currently widely used in the apparel industry, from large companies to small uniform brands. A typical example is in sporting events, where teams often request logos to be printed on jerseys using PET technology to ensure sharp images.

Advantages of PET printing

Fast production time

One of the biggest advantages of PET printing technology is production time. An order of 100 shirts takes only half a day for 2 workers when using PET printing. With its fast printing speed, PET printing has become the optimal choice for event uniforms.

Sharp images and a variety of colors

PET printing technology also allows for rich colors and sharper images compared to traditional technologies. This is very important in the uniform industry, as the prominence and uniqueness of the logo or clothing design often determine the brand's impression.

Disadvantages of printing on PET

High initial investment cost

One of the drawbacks of PET printing technology is the relatively high initial investment cost. The adoption of this technology requires manufacturers to invest in modern equipment and technology, which can create barriers for small businesses.

Difficulties in the small-scale production process

PET printing technology is most suitable for large orders due to high fixed costs. This can pose challenges for businesses that want to produce small quantities or trial samples, as the cost per product in smaller orders can be much higher than expected.

Product durability

The durability of the print may decrease when washed too many times or washed with strong detergents. Using washing machines that use hot water or drying at high temperatures can also affect the quality of the print.

On average, a PET print will maintain absolute quality for 30-35 initial washes. Due to this drawback, PET printing is used for event uniform samples with a short lifespan.

The future of PET printing technology in the uniform industry

Development trend

In the future, PET printing technology may continue to develop with new applications and modern technology. The integration with environmentally friendly printing technologies could create uniform products that are both durable and environmentally protective.

Sustainable solutions

To address environmental issues, many manufacturers are seeking solutions for PET printing technology, such as using natural inks or improving the production process to minimize waste. This not only helps protect the environment but also enhances the brand image in the eyes of consumers.

Summary

PET printing technology offers many benefits in the uniform industry, especially in terms of time and sharp print quality. However, investment costs and durability are factors that need to be considered when applying this technology. Companies should carefully consider the above factors to make a reasonable decision.

Frequently Asked Question

Can PET printing technology be used for all types of fabrics?

PET printing technology can be used for many types of fabrics, but the most effective are fabrics with compatible materials such as polyester.

2. Is the price of uniform T-shirts printed with PET higher than those printed with other technologies?

The cost of PET printed uniform T-shirts is often higher due to production costs and higher durability, but this is a reasonable investment for long-term product quality.

3. Can complex designs be printed on uniform t-shirts?

Yes, PET printing technology allows printing complex designs in a variety of colors without losing image quality